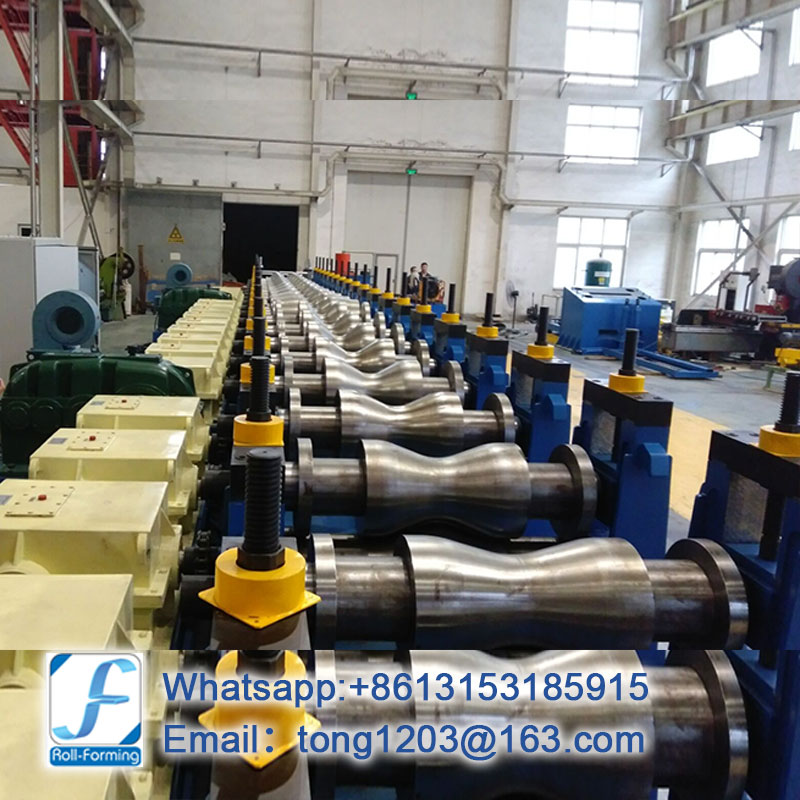

corrugated board machine equipment Custom drawing

1.De-coiler storage steel coils and smoothly feeding into forming machine labor save operation. 2. Forming, Punching & cutting at any required length with pre-set quantity automatically. 3.The encoder will record signal feedback and showing exact length of product on display. 4.The total length of finished coil is able to calculate via control panel. 5.Steel rollers are fabricated by CNC precision machine and hard chrome coated. 6.Cutting blade material is Cr12/Cr12Mov (D2/D3) fabricated by CNC machine, heat treatment. 7. Hydraulic system will equip cooling system to keep low temperature during long time continuously in one day.

Corrugated Metal Roofing Making Machine

Crimp roofs use a sequence of steel sheets that are related from eave to ridge using an exposed fastening machine. Crimp panels normally require a sturdy roof deck with a water-evidence membrane.

if customers want to make crimp roofs, you need most effective most effective buy crimping machine, but moreover steel roofing machine, because

we make steel roofing from roofing machine, then feed roofing to crimping machine to make roofing crimped or curved.

crimping machine or curving machine consist of three feed rollers, crimping device, hydraulic station which give strength to crimp,

siemens or mitsubishi plc manage machine.

you could choose out crimping or curving shape or degree.

this crimping machine is traditional , strength through manner of method of usual motor , so curve about 12 times in line with minutes

if you need curve extra fast, we have got were given curve machine strength through manner of method of servo motor 1.5kw.

machine can curve about 20 times or extra in a unmarried mimutes.

Main parameters of machine:

Suitable material: cold-rolled and heat-treated galvanized steel strip

Yield strength: 235MPa

Thickness of raw material: 0.3~0.6mm

Forming speed: about 10 to 12m/minute

Main motor power: 15kW

Hydraulic station power: 5.5kW

Controlling system: PLC and converter

Voltage: 380V, 3-phase, 50Hz

Total weight: about 6.5 to 9T

Material of roll former system:

Main rollers of this line are made by number 45 steel material, all treated by full CNC precision machines, surface are plated with chrome

Active shaft: high grade number 45 carbon wrought steel

Cutting blade: Cr12 mold steel with quenched treatment, change cutting blade manually when make various sizes of products

Quality grantee: offer 12-month time starting from date of delivery

Sale after service: offer sale after service for life

Jinan roll forming machinery engineering inc. specialized in all kinds of roll forming machines, such as,

Highway Guardrail Roll Forming Machine,

High Speed Multi-Station Hydraulic Machine,

Guardrail Board Production Line,

Anti-Collision Beam Production Equipment,

Corrugated Board Cold Bending Production Line,

Shelf Column Production Line,

Photovoltaic Bracket Production Equipment,

Car Side Panels Production Equipment,

and other machines designed to customers requirement.

Jinan Ruifu Mechanical Engineering Co., Ltd. is a high-tech industrialized entity composed of senior expert engineers and technicians who have been engaged in the design and manufacture of stamping automation and cold bending equipment for many years. It is mainly engaged in the design, development and manufacture of metal forming technology and sheet metal machinery. It is committed to the development of stamping automation, cold bending equipment and factory solutions, high-speed punching equipment and molds, and provides the whole line of hydraulic and electrical control technology.

Contact: Manager Xu +86 13153185915 +86 0531-87518718