Single facer corrugated board machine Timely delivery

Adopt standardized design and mass production in the factory; Short production cycles and high efficiency are good for reducing costs and improving quality.The site installation speed is fast, the construction period is short, and the social and economic benefits are obvious.construction can be carried out throughout the year, the construction is not affected by the season and the environment.

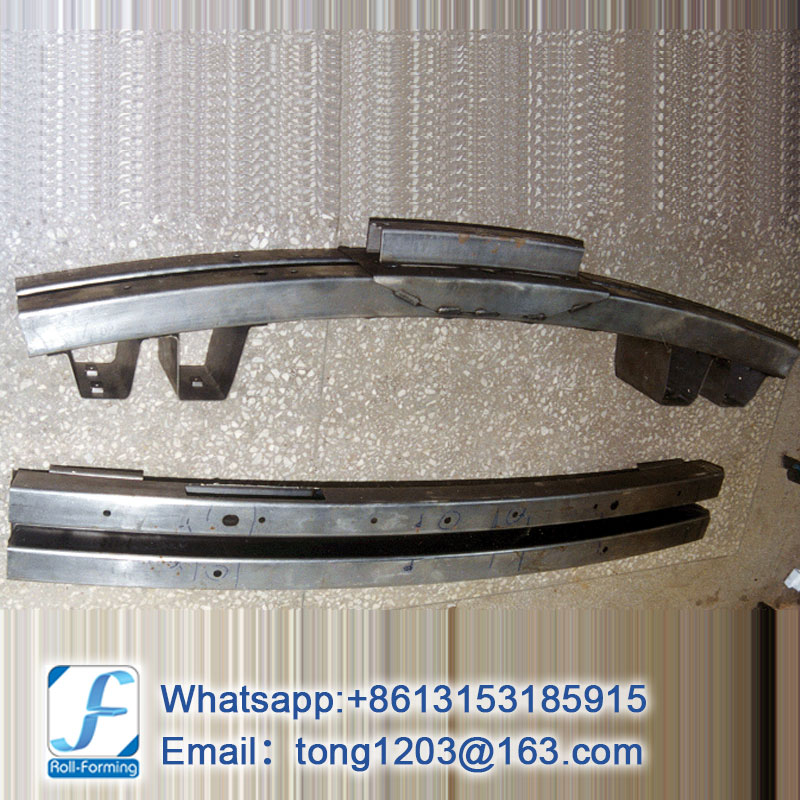

The Crash Barrier Roll Forming Machine end up designed and built to deliver the W usual beams for crash barriers or highway guardrails from 3.0-4.0mm thickness galvanized steel and the guardrails can be used for the improvement of highways and expressway. The shape of the crash barriers or the W beams is typically just like regular type withinside the world. The entire roll-forming line is certainly robotically going for walks beneath the PLC control system, which incorporates feeding, leveling, punching, roll forming tool and cutting, This tool can produce U segment for mounting or assist for highway guards.

Product Attributes

Brand: RUIFU

place of origin: China

status: New

Marketing type: Ordinary Product

Core component w.. .: 1 Year

Core components : Plc, Gearbox,Motor

warranty period: 1 Year

Core selling point : Sustainable

Out-of-warranty ser...: Video Technical Support, Online Support, Spare

Parts, Field Maintenance And Repair Service

Where to provide l... : Malaysia, Kenya,Egypt,ltaly,Viet Nam,Brazil,

Applicable industry : Manufacturing Plant, Construction Works, Other

Peru, Indonesia,India,Mexico,Russia,Thailand

Showroom location...: Malaysia, Egypt, United States,Italy, Viet Nam,

Brazil, Peru, Indonesia, India,

Russia, Thailand

Steel Plate After Sli...: Q345b 610l

ID: 610mm

strip Width: 600mm

weight: ≤10000kg

oD: ≤1600 Mm

Yield Strength: ≤500mpa

Tensile Strength: 650mpa

Max.Thickness: 6-12mm

Jinan roll forming machinery engineering inc. specialized in all kinds of roll forming machines, such as,

Highway Guardrail Roll Forming Machine,

High Speed Multi-Station Hydraulic Machine,

Guardrail Board Production Line,

Anti-Collision Beam Production Equipment,

Corrugated Board Cold Bending Production Line,

Shelf Column Production Line,

Photovoltaic Bracket Production Equipment,

Car Side Panels Production Equipment,

and other machines designed to customers requirement.

Jinan Ruifu Mechanical Engineering Co., Ltd. is a high-tech industrialized entity composed of senior expert engineers and technicians who have been engaged in the design and manufacture of stamping automation and cold bending equipment for many years. It is mainly engaged in the design, development and manufacture of metal forming technology and sheet metal machinery. It is committed to the development of stamping automation, cold bending equipment and factory solutions, high-speed punching equipment and molds, and provides the whole line of hydraulic and electrical control technology.

Contact: Manager Xu +86 13153185915 +86 0531-87518718