Guardrail roll forming machine After sales guarantee

Can produce a variety of specifications of guardrail, can also be customized according to the customer's requests, to meet the needs of all customers.

Characteristics of Guardrail Roll Forming Machine For Sale

Our Guardrail Roll Forming Machine has the subsequent characteristics:

1.Can produce quite a few specs of guardrail, also can be custom designed in line with the customer's requests, to satisfy the wishes of all customers.

2.High efficiency, manufacturing accelerate to twenty-five m/min.

3.Modular layout and manufacturing, components regular charge is high, easy maintenance.

4.The more desirable layout of the mainframe shape and first-class manipulate lets in us to supply thicker plates for you.

5.All the processing of the frame is completed at one time, and the advanced device device ensure the accuracy of the dimensions and function of each fit, simply so our molding unit almost does now not need repeated debugging, with very little dependence on personnel.

6.The computerized application manage era is adopted, the parameter putting is straightforward and convenient, the diploma of automation is high, the gadget is self-mastering cappotential is strong, the manage gadget makes use of the awesome brand, the performance is stable, the man-gadget interplay interface is kind.

7. Through electrical control, the production of products with multiple specifications, sizes, different hole shapes, product thickness and length can be realized, Automatic feeding, automatic punching, fixed-length cutting, accurate and reliable, and automatic stacking, packaging and other functions can be configured without manual operation to switch any parts, reducing labor cost, reasonable product structure, pleasing to the eye and high production efficiency.

8.Products have strong bending compression performance, straightness is good, strong and durable, it can realize close lap. Compared with other production process technology, no heat, no carbon, and other harmful gases, environmental production, can be used as factories, warehouses, engine garages, hangar, exhibition halls, theaters, stadiums, bazaar, mounted and other building roofing load-bearing load and metope.

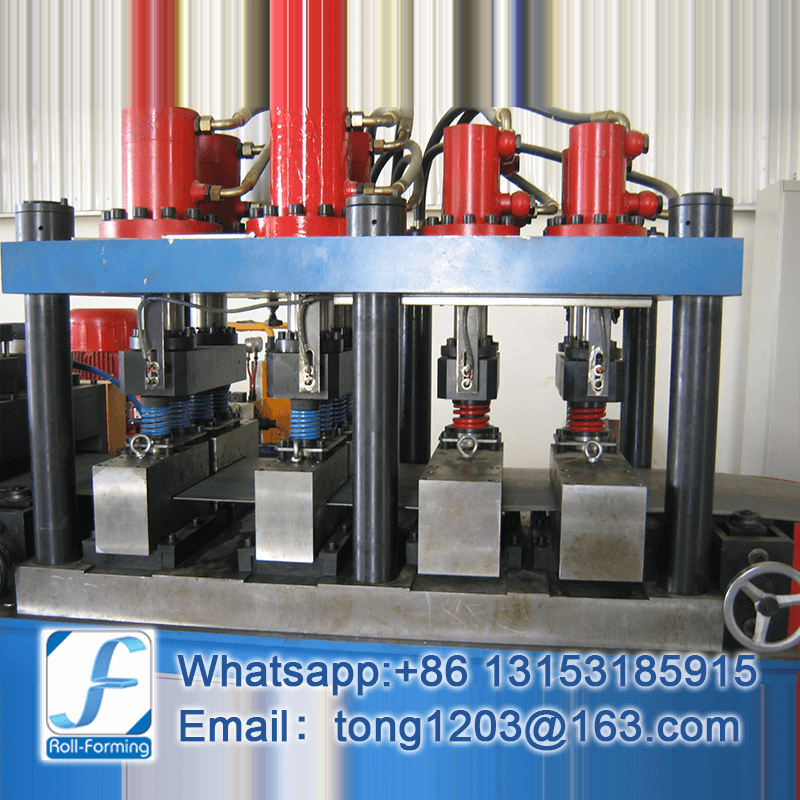

Machine Details:

1. Machine technical conditions:

Machine cover an area of 1.1:35 * 3.5 * 5 meters (length x width x height).

Devices feed direction: to be determined.

Voltage parameters of 380, 50 Hz, 3 phase.

Hydraulic oil: 46 # hydraulic oil.

Gear oil: 18 # hyperbolic gear oil.

2 Machine main technical parameters:

Width: 570 mm or less

Thickness: 3 ~ 4 mm

Material: low carbon steel, etc

Length: 4000 mm

2.5 Machine installed gross capacity: 79 kw.

3. Forming Part:

Velocity: 0 ~ 10 m/min.

Molding time: 22 time/min

Memorial arch for slider QT450 castings for casting (HT300) casting forming, annealing, rough machining, finish machining.

Diameter of axle: Φ 95 mm. Material: 45 # steel

Processing: rough machining to tempering treatment, finish machining

Forming roll: material GCr15 steel heat treatment: HRC58 ~ 62 °

Processing: rough machining, heat treatment and finish machining

Transmission way, 200 gearbox shaft driving. Front-rear 3 groups and gear drive, stable transmission, high precision molding.

Motor, power 30 kw motor 1 650 deceleration machine

The fuselage part is the main body of the mill, as the channel steel welded with 35 mm plate CNC machining, beautiful and firm base installation adjusting bolt, used to adjust the fuselage level, base mounting hole for hoist, installation convenient transportation.

Jinan roll forming machinery engineering inc. specialized in all kinds of roll forming machines, such as,

Highway Guardrail Roll Forming Machine,

High Speed Multi-Station Hydraulic Machine,

Guardrail Board Production Line,

Anti-Collision Beam Production Equipment,

Corrugated Board Cold Bending Production Line,

Shelf Column Production Line,

Photovoltaic Bracket Production Equipment,

Car Side Panels Production Equipment,

and other machines designed to customers requirement.

Jinan Ruifu Mechanical Engineering Co., Ltd. is a high-tech industrialized entity composed of senior expert engineers and technicians who have been engaged in the design and manufacture of stamping automation and cold bending equipment for many years. It is mainly engaged in the design, development and manufacture of metal forming technology and sheet metal machinery. It is committed to the development of stamping automation, cold bending equipment and factory solutions, high-speed punching equipment and molds, and provides the whole line of hydraulic and electrical control technology.

Contact: Manager Xu +86 13153185915 +86 0531-87518718