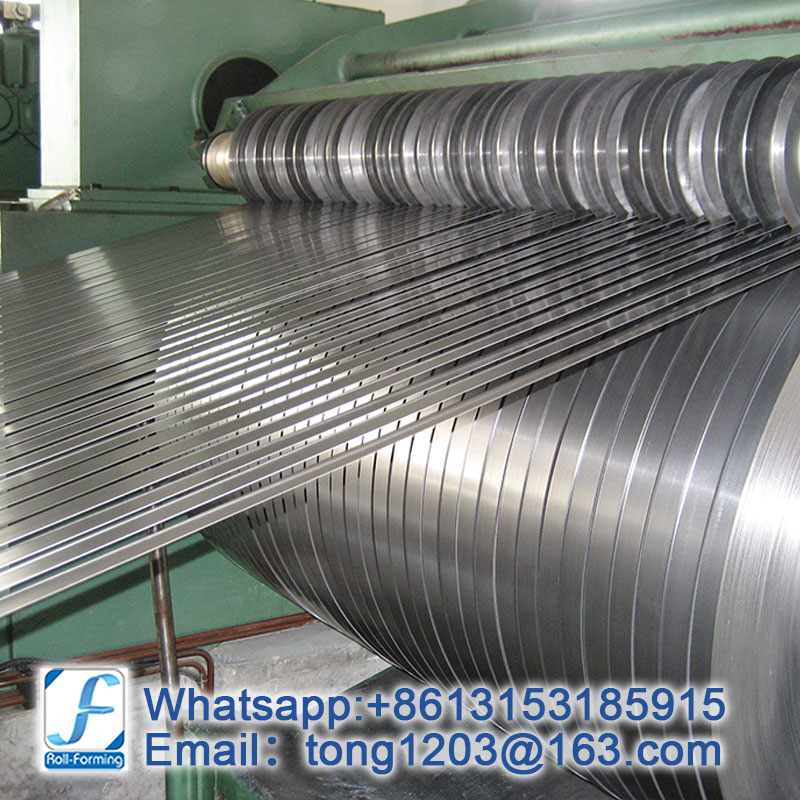

High Speed Coil Slitting line

More intelligent

Highly automated procedures, reduce manual operations, improve work efficiency, and improve enterprise productivity;

More stable

The production process of the whole process is stable, and the quality and consistency of products are improved;

Lower cost

Raw materials are saved by about 5%, labor is saved by about 8 people per equipment, the efficiency is increased by three times, mass production, and the production cost of the enterprise is reduced.

Fast delivery of spot goods from professional manufacturers

Manufacturer direct sales / support customization / short delivery time

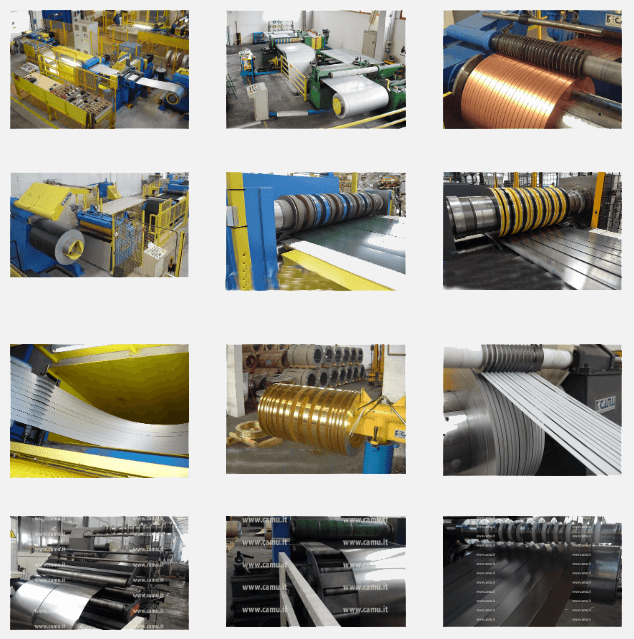

Our manufacturing is able to protecting all of the clientele’s desires and is split into classes on the idea of dimensions and thickness of the fabric to system and manufacturing quantities. These parameters make it essential to divide the cut-to-duration slicing strains into LIGHT, MEDIUM and HEAVY.

LIGHT up to fifteen Ton, 1550 mm, thickness from 0.2 mm to a few mm, hastens to 200-350 m/min MEDIUM as much as 30 Ton, 1600 mm, thickness from four mm to 12.7 mm, hastens to one hundred fifty m/min HEAVY as much as 35 Ton, 2200 mm, thickness from eight mm to sixteen mm, hastens to 20-forty m/min The slitting traces are consequently capable of paintings thickness from 0.2 mm to sixteen mm with operating speeds that variety from 20 to 350 m/min relying at the desires of the precise customer.

SLITTING LINES – LIGHT

LIGHT up to 15Ton, 1550mm, sp. da 0,2mm a 3mm, velocity up to 200-350 mt/min

SLITTING LINES – MEDIUM

MEDIUM up to a 30Ton, 1600mm, sp. da 4mm a 12,7mm, velocity up to 150 mt/min

SLITTING LINES – HEAVY

HEAVY up to 35 Ton, 2200mm, sp. da 8mm a 16mm, velocity up to 20-40 mt/min

SLITTING LINES – MINI SLITTER

MINI SLITTER up to 3Ton, 1300mm, sp. da 0,2mm a 3mm, velocity from 60 mt/min up to 150 mt/min

PLC, touch screen, encoder, sensor and other electrical brands:

Brand of hydraulic valve:

Brand of pneumatic components:

Bearing brand:

WHY CHOOSE US?

★. Over 20 years of professional experience in roll forming industry, nearly 10 years of RUIFU experience for

Taiwan roll forming machines and one of China TOP 3 high quality roll forming machinery manufacturers

and exporters (RUIFU hass exported to over 80 countries and regions)

★. ISO 9001 certified company, Taiwan roll forming technology and CE centificate issued by SOS ensure the

high quality of RUIFU roll forming machines.

★. 6 factories with 30000 ml 200 skilled workers and 6 machining centers ensure Factory Direct Price and

Fast Del ivery.

★. Support Refund Money Agreement in case of bad quality.

★. Industry's best warranty in China 2 years parts & 2 years labor and 7x24 award wining customer service

within 24hours

PACKING AND LOGISTICS

OUR CUSTOMER

FAQ

How can customers be assured that UIFU will deliver quality roll forming machines?

1.Customers can send their engineers of thirty party to RUIFU faclory 1o inspect the

roll forming machines before delirery.

2 UIFU can send the ted hnicians to the buyer's factory for the installation of the machines.

3. UIFU oflered award winning customer service is free of charge during the 2 years warranty period.

How can the customer install the machine when it arrives?

RUIFU engineers wil 00 10 your sde once you pel your machines and your faclory is resdy(including electricity. testing materials, hydraulic oil, Auoiliary stalf, Transport and lifting derice, etc ) for commission, they will and teachingyour technicians how to run the machines UIFU engineers can't visit your side for senvice because of pandemic,UIFU will offer on line support and video technical support.

Does UIFU provide customized roll forming service?

Yes. The aim of the service s to design innovative sheet metal products according

to customers' wishes and the latest maket tends. Experienced UIFU designers

frem Chins mainland and Taiwan, South Kares and Europe are at your senvice if you

are looling for new profiles or features that change the rules of the game.

■Feasbilty studies and profile sketching

■3d modelling and simulation

BUSINESS PRODUCTS

Jinan roll forming machinery engineering inc. specialized in all kinds of roll forming machines, such as,

Highway Guardrail Roll Forming Machine,

High Speed Multi-Station Hydraulic Machine,

Guardrail Board Production Line,

Anti-Collision Beam Production Equipment,

Corrugated Board Cold Bending Production Line,

Shelf Column Production Line,

Photovoltaic Bracket Production Equipment,

Car Side Panels Production Equipment,

and other machines designed to customers requirement.

CONTACT US

Jinan Ruifu Mechanical Engineering Co., Ltd. is a high-tech industrialized entity composed of senior expert engineers and technicians who have been engaged in the design and manufacture of stamping automation and cold bending equipment for many years. It is mainly engaged in the design, development and manufacture of metal forming technology and sheet metal machinery. It is committed to the development of stamping automation, cold bending equipment and factory solutions, high-speed punching equipment and molds, and provides the whole line of hydraulic and electrical control technology.

Contact: Manager Xu +86 13153185915 +86 0531-87518718