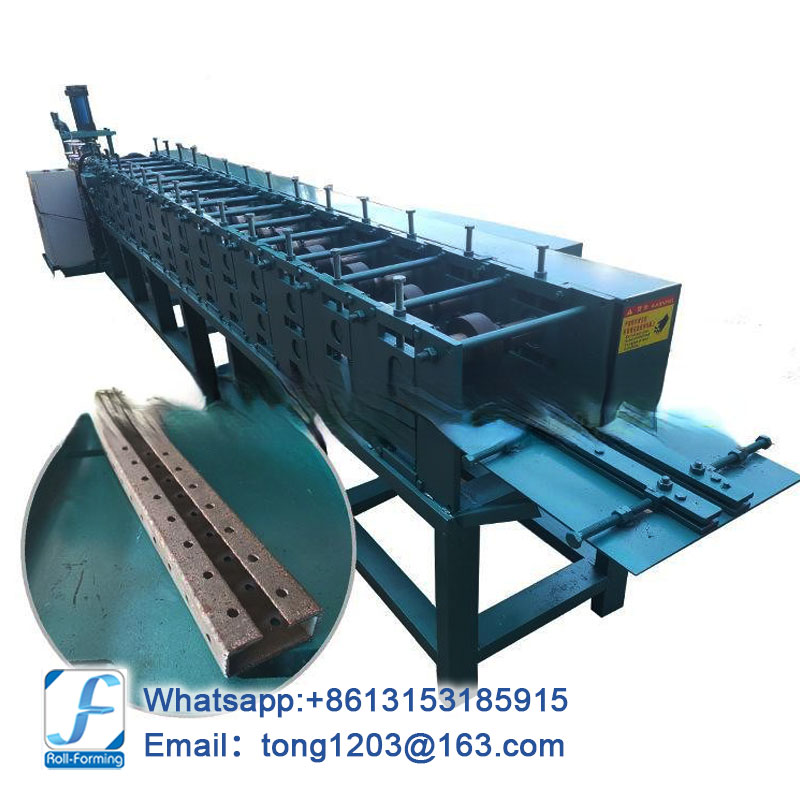

Storage rack column cold roll forming production line

More intelligent

Highly automated procedures, reduce manual operations, improve work efficiency, and improve enterprise productivity;

More stable

The production process of the whole process is stable, and the quality and consistency of products are improved;

Lower cost

Raw materials are saved by about 5%, labor is saved by about 8 people per equipment, the efficiency is increased by three times, mass production, and the production cost of the enterprise is reduced.

Fast delivery of spot goods from professional manufacturers

Manufacturer direct sales / support customization / short delivery time

The Storage Rack Roll Forming Machine is mainly used for the production of storage racks. The steel sheet material is unfolded, levelled, perforated, continuously roll formed and automatically cut to length. For the processing of different types of profiles we offer the Shelf Back Layer Roll Forming Machine, the Shelf Bracing Roll Forming Machine, the Rack Roll Forming Machine, the Shelf Stud Roll Forming Machine Machine, Shelf Upright Column Roll Forming Machine and other different cold-forming machines.

Product Attributes

Model No.: HJLZ

Brand: Raintech

place of origin: China

status: New

Video factory inspection: Provided

Mechanical test report: Provided

Marketing type: Ordinary Product

Core component warranty period: 1 Year

Core components: Plc, Gearbox, Motor

warranty period: 1 Year

Core selling point: Sustainable

Out-of-warranty service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where to provide local services (in which countries are there overseas service outlets): Malaysia, Kenya, Egypt, Italy, Viet Nam, Brazil, Peru, Indonesia, India, Mexico, Russia, Thailand

Applicable industry: Manufacturing Plant, Construction Works, Other

Showroom location (in which countries are there sample rooms overseas): Malaysia, Egypt, United States, Italy, Viet Nam, Brazil, Peru, Indonesia, India, Russia, Thailand

Coils Weight: ≤5000 Kg

Material: Q235

Coils ID: Ф508±10 Mm

Infeed Coils Width: ≤400mm

Strips Thickness: 2~2.5 Mm

Max. Coil OD: 1400mm

Supply Ability & Additional Information

Packaging: wooden package or non package according to customer's requirements

Productivity: 20 sets per month

Transportation: Ocean,Air,Land

Place of Origin: Shandong, China

Supply Ability: 20 sets/month

Certificate: CE/ISO

HS Code: 8453200000

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,Express Delivery

Packaging & Delivery

Selling Units:

Set/Sets

Package Type:

wooden package or non package according to customer's requirements

Picture Example:

Material : Q235

Coils ID: Ф508±10 mm ,

Infeed coils width: ≤400mm

Strips thickness: 2~2.5 mm

Max. coil OD: 1400mm

Max. coil weight: 5000kg

Other specifications of Goods Shelving Racking Making Machine:

Power : 380V±10%;

It can operate continuously and stably 24 hours in the following working conditions

Ambient temperature:2℃~45℃,relative humidity:≤90%(25℃)

Three phase AC power:380V(±10%),50HZ

Single-phase AC power supply:220V(±10%),50HZ

Sheet precision and selection requirements: the camber value of the sheet material used in the roller press line (after longitudinal shear) at least reach to(1‰)。

Total power: approx..75kw Overall Size: approx..20000 X4000mm

Line direction: left→right(according to customer requirement)

Process of the Steel Metal Srorage Forming Line

Uncoiler →loop(storage)→servo feeding→punching →roll forming→cutting →finished products

Pic Show:

PLC, touch screen, encoder, sensor and other electrical brands:

Brand of hydraulic valve:

Brand of pneumatic components:

Bearing brand:

WHY CHOOSE US?

★. Over 20 years of professional experience in roll forming industry, nearly 10 years of RUIFU experience for

Taiwan roll forming machines and one of China TOP 3 high quality roll forming machinery manufacturers

and exporters (RUIFU hass exported to over 80 countries and regions)

★. ISO 9001 certified company, Taiwan roll forming technology and CE centificate issued by SOS ensure the

high quality of RUIFU roll forming machines.

★. 6 factories with 30000 ml 200 skilled workers and 6 machining centers ensure Factory Direct Price and

Fast Del ivery.

★. Support Refund Money Agreement in case of bad quality.

★. Industry's best warranty in China 2 years parts & 2 years labor and 7x24 award wining customer service

within 24hours

PACKING AND LOGISTICS

OUR CUSTOMER

FAQ

How can customers be assured that UIFU will deliver quality roll forming machines?

1.Customers can send their engineers of thirty party to RUIFU faclory 1o inspect the

roll forming machines before delirery.

2 UIFU can send the ted hnicians to the buyer's factory for the installation of the machines.

3. UIFU oflered award winning customer service is free of charge during the 2 years warranty period.

How can the customer install the machine when it arrives?

RUIFU engineers wil 00 10 your sde once you pel your machines and your faclory is resdy(including electricity. testing materials, hydraulic oil, Auoiliary stalf, Transport and lifting derice, etc ) for commission, they will and teachingyour technicians how to run the machines UIFU engineers can't visit your side for senvice because of pandemic,UIFU will offer on line support and video technical support.

Does UIFU provide customized roll forming service?

Yes. The aim of the service s to design innovative sheet metal products according

to customers' wishes and the latest maket tends. Experienced UIFU designers

frem Chins mainland and Taiwan, South Kares and Europe are at your senvice if you

are looling for new profiles or features that change the rules of the game.

■Feasbilty studies and profile sketching

■3d modelling and simulation

BUSINESS PRODUCTS

Jinan roll forming machinery engineering inc. specialized in all kinds of roll forming machines, such as,

Highway Guardrail Roll Forming Machine,

High Speed Multi-Station Hydraulic Machine,

Guardrail Board Production Line,

Anti-Collision Beam Production Equipment,

Corrugated Board Cold Bending Production Line,

Shelf Column Production Line,

Photovoltaic Bracket Production Equipment,

Car Side Panels Production Equipment,

and other machines designed to customers requirement.

CONTACT US

Jinan Ruifu Mechanical Engineering Co., Ltd. is a high-tech industrialized entity composed of senior expert engineers and technicians who have been engaged in the design and manufacture of stamping automation and cold bending equipment for many years. It is mainly engaged in the design, development and manufacture of metal forming technology and sheet metal machinery. It is committed to the development of stamping automation, cold bending equipment and factory solutions, high-speed punching equipment and molds, and provides the whole line of hydraulic and electrical control technology.

Contact: Manager Xu +86 13153185915 +86 0531-87518718